Government yesterday held firm to its position that there is a national shortage of stone that warrants importation to cushion both demand and price.

“I want to say emphatically that there is a stone shortage in Guyana… Everyone knows that for the past two years there has been a stone shortage and it continues to exist,” Minister of Public Works Robeson Benn told a press conference.

President Donald Ramotar had recently announced that stone would be imported to cover the shortage.

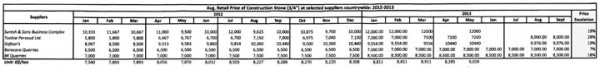

Benn said shortage indicators include price increases, with the price of stone going up an average of 18% in the last two years. He said too that stone was already being imported by persons and that concretises government’s stance on the need to import the commodity.

He said government would like to see stone being sold to consumers at around $6,000 to $7,000 per tonne, instead of the current $8,000 to $8,500 per tonne price. Imported stone is currently being retailed at between $8,000 and $9,000 per tonne, while at some retailers consumers pay as much as $12,000 per tonne for local stone.

Benn informed that before briefing the President on the shortage, his ministry would have undertaken studies countrywide analysing both domestic and industrial demand and supply. These were backed up by information from the Guyana Geology and Mines Commission, which declares that quarry products by all five licensed quarry operators totalled 483,859 tonnes. BK International’s contribution is 277,103 tonnes and it averages a monthly production of 23,000 tonnes.

Benn said the average monthly demand for aggregates in 2012 was 97,000 tonnes alone for public works projects.

Home builders have long complained of work being stalled because suppliers told them that stone was not available.

No shortage

Managing Director of BK International Brian Tiwari had earlier this week rejected the President’s claim, saying that he was badly informed.

Tiwari had asserted that as at Monday last his company had some 10,000 tonnes of stone at its Water Street, Kingston location, while another 10,000 tonnes remained at its quarry in Essequibo. He said BK produces approximately 30,000 tonnes of stone daily, which, using its ships, it quickly delivers to contractors in Demerara, Berbice and Essequibo.

The company’s Director of Material Supplies Gail Tiwari had stated that the company had no outstanding supply contract with any contractor. This, Brian Tiwari said, was testament to the fact that there was no shortage, while adding that the perceived shortage was a result of contractors not having sufficient finances to immediately pay for the materials they need.

According to Gail Tiwari, because they are turned away for not being able to provide cash on demand, contractors seem to have concluded that they have not been supplied because there is no supply. This perception may have something to do with the payment system employed by the company. Gail Tiwari said that several years ago contractors were able to receive materials on credit but this has changed.

Over the last two years, she said, contractors have amassed credit accounts with the company to the tune of $50 million; a sum which the company is not willing to go past, especially since collecting these outstanding amounts is proving to be a challenge.

Even the Ministry of Public Works, Brian Tiwari had said, would take up to six months before making payment for goods and services to BK. As a result, a hold has been put on the credit system and all contractors are now required to make cash payments for materials before they are supplied. Gail Tiwari said that while BK would like to help consumers, the company also has to consider its financial position and must focus on ensuring that all of its financial obligations are met.

The company criticised stone importation, saying that the alternative stone was slate stone, an inferior type. Tiwari said studies conducted to test the stone’s quality against its local counterpart have revealed that slate stone is inferior that what is supplied in Guyana and should not be used in construction.

Omar Persaud, a Geologist with BK, had explained that the stone produced in Guyana is one of the highest grades of igneous rock. Such rocks, he said, are large and when subjected to tests come out ahead of slate stone which is claimed by some to be a subsection of the igneous rock family.

Explaining the test results carried out by BK’s labs on the two types of stone, BK Project Engineer Julian Archer said slate stone was found to have a higher absorption percentage which means that more asphalt will be required to complete the construction of roads. Tests also showed that slate stone has a higher wear index, and a lower load strength index than its locally produced counterpart. This translates into a road or building which is not ideal for Guyana’s weather and the volume of vehicles which traverse our roads constantly. Despite the shortcomings pointed out though, slate stone is said to be sold at a higher cost than the locally produced stone.

‘Unhealthy situation’

As he produced samples of both local imported stones, Benn blasted BK for its critique, saying that scientific tests prove that they both were of same quality.

On the issue of payment, he yesterday produced records of payment to BK so far for the year which revealed that over $305 million and US$754,605 had been paid.

Benn said his ministry advised government to give consideration to the continued and increased importation of stone for four main reasons. He noted that over the past few years, the quarries have not been producing enough to satisfy the domestic market and that concrete and aggregate producers have had to import stone to militate against the domestic shortfall. “Contractors have repeatedly complained that some quarry products were being rationed by the suppliers. This high demand chasing very low supply has led to an unhealthy situation of price escalation and poor time performance by contractors generally,” he said.

Benn said observations of quarries in Essequibo and Mazaruni have shown that there is very little activity and few stockpiles of aggregates on the sites.

In addition, the quality of crusher run being supplied by one quarry operator has repeatedly failed sieve analysis tests and is considered unsuitable as a road base material. “These tests identified the scalping out of the midsize range of aggregates leaving an off-spec product with too much fines and crusher run,” Benn said.

He believes that in addition to the stone shortage that there has been hoarding by some suppliers.

He opined that BK’s newfound satisfactory supply of stone was due to the fact that it was no longer supplying contractors building the Marriott Hotel, as work there has come to a standstill.

He said the objective of the government was to have quality stone supplied to locals at competitive prices. “We want to have a competitive sustainable source of supply,” he said.