Controversy over mercury use in mining activity and its impact on the environment has impacted significantly on the image of the mining sector in Guyana. Over time, however, the Guyana Gold and Diamond Miners Association has moved closer to embracing the importance of environmental safeguards and has said that it is open to non-mercury methods that protect the environment while ensuring the continued viability of the industry.

The World Wildlife Fund has drawn local attention to non-mercury mining methods that have been successfully employed in French Guiana and the GGDMA has taken the significant step of publishing an abridged version of the French Guiana document for local miners.

In this issue Stabroek Business reproduces a copy of the document.

INTRODUCTION

On November 18, 2008, a team of personnel from the Guyana Gold and Diamond Miners Association (GGDMA) visited the Delfrancky mine in French Guiana. This was a collaborative effort between the GGDMA and the World Wildlife Fund (WWF). The exercise stemmed from the need for development of more environmentally friendly methods in gold processing and recovery in Guyana’s mining industry. The French Government has already initiated steps in regulating their mining sector, thus the opportunity was presented for a firsthand experience with what currently obtains there, with the intent that new insight can be had towards the improvement of Guyana’s mining industry.

The purpose of the visit to the Delfrancky mine in French Guiana was twofold in that it allowed us to witness mercury-free methods in the gold recovery process, as well as to witness firsthand the methods for progressive reclamation during exploration for gold. During the visit, there were demonstrations of three different methods of mercury-free gold mining techniques, namely, the use of the Shaking table, the use of Centrifugal Concentrators (Knelson), and use of the Gravimetric Table (also referred to as ‘long tom’). In addition to the demonstrations, the visiting team was shown a step by step reclamation activity which is currently being employed at the mining camp. We were also able to have a walk-through of a plant nursery having local species which are used to replant mined out areas.

General Findings

● Mercury use is prohibited in the processing of alluvial gold in French Guyana

● Progressive reclamation and re-vegetation are deciding factors in obtaining exploration permits.

● Discharge limits are higher than those stipulated in our regulation.

● Prospecting activities are required before any mining permit can be issued.

The French government has taken the first step to restrict mercury use by making mercury free mining methods mandatory in the processing of alluvial gold. Restoring mined out areas is also mandated by law, with a restoration programme being a requirement before a mining permit can be issued.

According to legislation passed in January, 2006 by prefectoral order (No1232/SG du 08 juin 2004), the French Government declared the use of mercury forbidden in the gold mining industry, and progressive reclamation is a prerequisite to mining. Mercury use in gold processing is a topical issue for decision makers since the majority of mining operations are situated on sites that were previously used, and the soil mercury content is very high. The content of mercury in the soil of French Guiana is 8 times higher than in France (soil of the region temperred climate). Owing to this dilemma, miners must confirm to strict environmental requirements if they are to apply for any of the mining permits discussed in the following section.

Their TSS/turbidity standard is 35mg/l – 250 NTU. Studies by the French governing agency resulted in it being changed from an original standard of 60mg/l TSS.

MERCURY-FREE ALTERNATIVES

The Mercury-free methods

The use of mercury-free alternatives in conjunction with enforcement of legislation has been instrumental in limiting the use of mercury in the amalgamation of gold in French Guiana. Some popular methods follow.

Shaking Tables are gravity concentrators with a laminar flow over an inclined surface. These work with a longitudinal vibratory movement, where mineral particles are differentiated by forming fan shaped bands according to their specific weight (and grain size). The tables are used to concentrate fine and ultra fine minerals. They have a processing capacity of 1.5 tonnes per hour. While the introduction of this type of equipment in Guyana will be advantageous, the price per unit will present a major challenge for small scale miners given the nature and approach to small scale gold mining in Guyana. In addition to the relatively high cost, this equipment requires a constant feed, constant supervision and electrical power feed, all of which may present further disadvantages for acquisition by local miners.

Centrifugal Concentrators are relatively cheap in comparison to Shaking Tables. These may cost as much as US$ 8,400 to set up. The method of operation is similar to the panning methods utilized by pork-knockers in our small scale sector; however, they can process greater volumes of pay material at a faster rate than manual methods can. According to the proprietor of the operation which we visited, it is possible to recover up to 80% of the gold in the pay material at the first attempt. Tailings can then be reworked to increase recovery rates. Under optimum conditions, centrifuges are able to recover ultra fine gold much better than other gravity concentration equipment. Below about 30 urn centrifuges are the only really efficient gravity concentration equipment. A limitation identified in the application of this method as well as with the Shaking Table is that they require a constant supply (pressure and quantity) of clean water.

The use of the sluice box is not new to small scale mining in the Guianas, however, in French Guiana, the sluice box is used twice in the gravimetric process. It is used both as a primary concentrator as well as a secondary concentrator. A sluice box is first used to obtain a concentrate from processing the pay material, after which, the long tom is used to process the concentrate obtained from the pit.

PROGRESSIVE RECLAMATION

As stipulated by legislation, a miner must detail in his application for a small scale mining permit (AEX) a plan for progressive reclamation of the site during exploration. During exploration of the site, the miner has the responsibility to reclaim 500m of the site before moving to another site (see the basic plan used below). This reclamation process is necessary for several reasons. It restricts suspended solids in the water, allows for the eradication of stagnant water, eliminates the methylation of mercury, limits mosquito development thus reducing the spread of malaria, and a few others. On any 2000 meters of land, the four activities below are recommended.

500m

Replantation

Exploitation

Preparation

Reclamation

2000 M

From observations made while touring the mine, it was noted that the operation is fully mechanized. The use of excavators was deemed an absolute necessity to the production of the results witnessed at the Delfrancky mine.

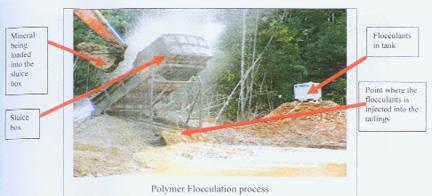

The mine site utilizes a closed circuit system, which results in zero discharge of tailings to surrounding water bodies. Polymer flocculation is used to treat tailings, and is applied at the exit of the Sluice Box. This process facilitates the ready settling of clay particles so that the water can be recycled. Flocculation is necessary where there is a high level of unsettled particles in water bodies. The unsettled particles allow discharged mercury to be trapped in soft sediments of rivers, and can be released through flash flooding and bottom fish feeding. The process of flocculant application is indicated below.

PROCESSING

Excavation

The excavator plays a pivotal role in the extraction of gold in French Guiana (Guyane). The excavator is employed from the start of the operation where the upper layer of the soil is cleared aside and stored for reclamation. It further removes the gravel material and stockpiles it not far from the sluice box. The excavator then periodically lifts the gravel material and feeds it into the sluice box where the material is washed.

Pumping System

The pumping system observed on the Delfrancky mine is similar to those employed in Guyana and Suriname in size (5”x6” outlet), however, there were some differences noted. The mine utilizes a system where the hose leading from the “pump was further divided into a two way system. The division created here indicates that the initial 5”x6” outlet is broken down into two 4” which does not mean more force. There is a further division which converts two to four and two and half inches (2%) outlets (see figure below). It seems however, that a greater force is created. While in some cases the techniques employed in the processing of gold are site specific, this, we believe, is a system which can be proposed to miners in Guyana.

Washing

The washing of the material in the sluice box is yet another mercury-free method utilized by the French. This allows for the removal of the large gold particles. The problem here is that the floor of the sluice box has riffles (thick traps, sometimes overt carpets) which create strong turbulence (necessary for the cascading effect). The riffles recover coarse gold efficiently, but generally lose the major portion of fine gold.

CONCLUSION AND RECOMMENDATIONS

With the increasing challenges to mercury use in the small scale mining industry and the problem it poses to human health, adopting alternative methods such as those utilized by our counterparts in French Guiana will help countries like Guyana and Suriname in tackling the problem of mercury contamination in small scale mining. In this regard, the following recommendations are given.

A general assessment of this French operation suggests that Guyana’s mining sector will need strategic transformation via the use of optimum dry-mining methods so as to replace conventional hydraulicking methods. In our opinion, this may exclude many small scale miners who do not have access to adequate finances with which to invest in purchasing the required equipment.

1. Proprietors in the small scale mining sector should be educated on advanced mining methods and techniques.

2. A changing technique in gold processing should facilitate proper reclamation in the Guyana’s gold industry.

3. There should be a positive attitude and awareness towards environmental issues in the mining industry.

4. Enforcement in collaboration with legislation should be emphasized.