Potential public and private sector buyers are yet to provide a verdict on the viability of introducing a South African-made product into Guyana’s road-building sector. The manufacturers have told Stabroek Business that SoilFix which has been successfully applied in major road-building products in South Africa and which has been tested in other countries in the Middle East, Africa and in Trinidad and Tobago, could significantly reduce road-building costs here.

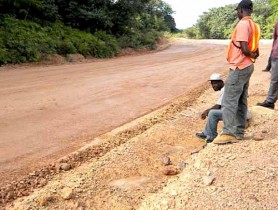

Neither government nor private contractors have as yet commented publicly on the outcome of tests conducted at Ituni to determine the effectiveness of SoilFix, a water-based polymer solution specifically developed as a soil binder for the stabilization of sub-base and base course layers for roads and pavements.

Discussions between government, municipal and private sector officials and the South African company Romix Industries on the possible use of the SoilFix product here are now more than a year old. A visit to Guyana last year by Romix Industries Chief Executive Officer Peter Prinsloo saw the completion of road-building tests at Ituni, organised by the Ministry of Works. Additionally, other Romix representatives who had visited Guyana told Stabroek Business that the company also held discussions with various private sector officials regarding the feasibility of applying SoilFix to poor interior access roads leading to major mining and timber harvesting sites in various parts of the country.

Romix officials told Stabroek Business that the SoilFix product can be applied in both urban road repairs and rehabilitation programmes as well as in the construction of major interior roads. The material, its manufacturers say, is applied to surfaces with water, using a tanker or bowser. The material is ripped or milled into the base or sub-grade material using a grader or mechanical stabilizer after which more water is added to the surface to achieve optimum moisture content for effective compaction. After three to five days a subsequent wearing course is applied.

The manufacturers say that the polymer content in the material will gravitate downwards to strengthen the sub-surface layer of the road while road longevity is increased and maintenance minimized since the flexible nature of the polymer does not allow for cracking in the base layer.

Additionally, they say that the application of SoilFix eliminates poorly layered road work since the sub-base of the roads on which the material is applied is strengthened due to the migration of the product from the base to the sub-base level.

Stabroek Business has learnt that while a cash-strapped City Hall has been stalled in its bid to pursue the East La Penitence road rehabilitation project using the SoilFix material, ROMIX has met officials of Region Ten to discuss the application of the material to road-building projects in Linden and its environs. According to the ROMIX official with whom this newspaper has spoken, approaches are likely to be made to Region Four officials in order to stimulate interest in the use of SoilFix in pothole filling and repairs to roads in communities along the East Coast Demerara.

This newspaper has also learnt that significant demand for SoilFix in Guyana and elsewhere in the Caribbean could see the setting up of a manufacturing facility in the region using raw materials imported from South Africa.