(Jamaica Gleaner) Nestlé Jamaica Limited has spent close to US$8 million to invest in expanding and upgrading its Supligen production line at its Bybrook plant in Linstead.

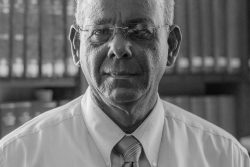

The new line is to be commissioned by the end of July, says General Manager James Rawle.

“Production volumes are not as healthy as they used to be. The plant produces for both export and local market but production volumes have fallen off significantly over the past few years. But we have spent US$7.6 million (J$676 million) to revamp the Supligen line and it should be up and running in about two weeks,” Rawle said.

Rawle did not specify the source of the financing but said it was by debt capital. Nestlé Jamaica is owned by Swiss giant Nestlé SA.

Rawle declined to discuss volume production, but said the new volumes would feed its domestic market, which is currently supplemented by imports, as well as the company’s export markets.

Supligen is generally imported when production levels are low at the factory, he said. The drink is sold in five flavours – vanilla, seamoss, peanut, strawberry and chocolate.

Overall, the Bybrook factory produces almost 75 per cent of all Nestlé products that are consumed in the local market, Rawle said. The company imports mainly juices, drinks and flavoured milk from Trinidad and exports milk-based products such as condensed milk, evaporated milk, skimmed milk and Milo to CARICOM and the United States.

Maggie, a Nestlé brand which is produced in Dominican Republic, is also imported.

The construction of the new Supligen line began last September, with new machinery already installed.

The new facilities will be fully automated, removing some of the manual process from the older line that is currently in operation, Rawle said.

The old production line involves a person loading the machine with individual cans from a perched position. The cans then move along the line and are closely monitored by the staff as it goes through the filling, pasteurisation, cooling and sealing process before the finished product exits the production room.

The new production line, which was on display last Thursday on a tour of the plant, will operate in a space seemingly twice the size.

The finished product will also be packaged in slimmer cans, like those used for energy drink Red Bull, and will cut the size of the product 367 ml down to 280 ml. The labelling will be bright blue and the product’s Actigen-E properties will remain strategically advertised on the label.

Rawle declined to say what the new product will cost.

The Gleaner was unable to get any feedback as to whether there will be corresponding price changes.

The supplement is marketed as “a meal in a can” and contains skimmed milk solids, sucrose, soya oil, corn syrup solids, defatted soya flour, iron saccharate, disodium phosphate, lecithin, carrageenan, nicotinamide, and fortified with Vitamins E, Calcium, Vitamins A, B1, B2, B6, C, D3, Folic Acid and Vitamin B12.

There are no locally produced rivals to Supligen in the milk-based energy drink but brands such as Ensure and Grace’s Nourishment which is imported from the UK are its competitor.

GraceKennedy said its Nourishment brand is not able to effectively compete with Nestle’s Supligen due to the current import duty structure.