In the wake of frequent breakdowns at the Uitvlugt Sugar Estate factory, GuySuCo has embarked on a major rehabilitation programme which aims to increase its efficiency and improve production in the first crop of this year.

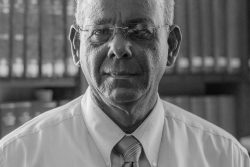

The first crop is scheduled to commence by mid-February with a target of 9,000 tonnes, the estate’s factory manager Brian Canterbury said yesterday, and employees are working assiduously to meet the deadlines before the commencement of the crop.

With an expansive rehabilitation programme planned, it was explained that some of the works will be staggered and completed during the out-of-production season.

Rehabilitation works are currently being executed on the Punt Dumper Area, Crystallizers, Boiler Chimneys and Power House.

During a tour organized by the Guyana Sugar Corporation (GuySuCo) yesterday, it was disclosed that the estate is in need of major rehabilitation since it has been in existence for 150 years and most of the infrastructure had deteriorated.

The rehabilitation works, Senior Communi-cations Officer Indira Badal said are being funded by money recently pumped into the industry by central government. Over the last five years, under the APNU+AFC-led government, GuySuCo has been pleading for revenue to improve its production capacity and execute major rehabilitation works.

The sugar union GAWU had also complained incessantly about factory problems at Utivlugt and workers went on strike in September last year in protest at the continuing difficulties.

As of December 28, 2020 the National Assembly has approved $4 billion for GuySuCo. Of this figure $2.1 billion will go towards the Albion Estate and $518M to the Blairmont Estate and the remainder to the Uitvlugt, Rose Hall, Skeldon and Enmore estates along with operating costs at the GuySuCo office.

Guy Romain, a Shift Manager, stated that they have commenced work to improve the efficiency of the crystallizers. He explained that there needs to be a complete renovation of the plant since it has suffered major deterioration over the years and has lost its effectiveness.

“Works will be done during this out-of-crop and next out-of-crop season because the crystallizers require a major overhaul. When this is done, it will help to boost our production and quality of sugar,” he related.

He added that they are also preparing to install new pumps to reduce congestion in the boiler house. This improvement will increase production and reduce its cost.

“We need to refurbish the whole system. What is happening with the current system is that from time to time the pumps will stall on us and when that happens it increases boiler house temperature levels and causes a ripple effect and affects the entire production because everything is slowed down,” he said.

Meanwhile, Shift Engineer Manager, Lochan Deokaran told reporters that the estate is looking to replace the gear turbines in the punt dumper area. He noted that with the aged and defective machinery, production has been hampered tremendously. The defective machinery, he explained, affects the free flow of cane to the mills and steam generation in the factory.

It was related that new units will see better performance and a vast reduction in stoppages and more efficient power supply.

Additionally, he pointed out that they are also conducting works on the cane washing system to make it more efficient. While they will not be able to completely install the new system for the upcoming crop, Deokaran pointed out that they are working to improve it.

Extraneous

“Extraneous matter such as mud and sand comes with the cane and are not always washed off. A new cane wash system will improve and aid in proper milling and steam generation. This will ultimately enhance sugar quality …,” he pointed out.

Touching on the rehabilitation of the boiler chimneys, Deokaran said they will be replacing both of the existing ones. The chimneys also posed a health and safety threat to workers.

“We are currently in preparation to replace one in time for the new crop. We have sourced a 3CR chimney from the (former) Wales Estate and this will be a significant boost to production,” he stated while noting that within the next two weeks they will be able to dismantle the existing structure and replace it.

Deokaran said that after the chimney is taken down they will have to construct a new foundation for the replacement. He also stated that they will have to build a completely new chimney since they have been unable to source another.

He added that the new chimneys will greatly reduce ash flow into the neighbouring communities. Residents have repeatedly complained about this.

The Shift Engineer Manager explained that they are also preparing to commence rehabilitation work on the 2.5 Megawatt Turbine Alternator which powers the estate.

“The power house has two issues we have to deal with. We have to replace the defective governor that controls the 2.5MW Alternator set that we have. The governor malfunctions and puts pressure on the swing loads causing fluctuations. So we have to replace it so we can maintain a proper steam generation and power supply to the entire estate,” he related.

He added that they also have to service the alternator as this was not done in recent years resulting in a buildup in dust in the router.

Since ascending to office in August last year, the Irfaan Ali-led government has been pumping money into the sugar industry in a bid to revive it.

In August last year, Minister of Agriculture Zulfikar Mustapha said that the three operating factories are in dire need of capital investments to cut frequent downtime. He noted that the Uitvlugt factory has been severely affected by mechanical issues.

“(The) capital programme suffered from a lack of funding and will result in future crops being adversely affected. For this year from a budget of $3.24 billion, the Corporation could only expend $82 million due to external funding not being made available,” he said.

Immediate past President David Granger was written to by then Chairman of the Board of GuySuCo, John Dow, last year on the corporation’s financial dilemma.

In May, Dow appealed to Granger “… to use your good offices to arrange for funding to prevent the impending closure of the industry.” In the letter, he also said that GuySuCo needed funds to be able to survive after the second week of June, 2020.

Dow had told the then President that the current estates – Albion, Blairmont and Uitvlugt – in 2015 were in dire need of upgrades and that considerable sums of money were required to fix the deteriorated infrastructure in the field, in particular, bridges, dams, revetment repairs, and to provide for replacement equipment in field tractors, drain-digging equipment etc and factory pumps, motors etc.