…in 40th anniversary year

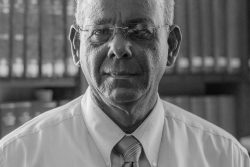

Higher standards of customer service, timely responses to market demand and price competitiveness are among the critical tools being employed by the National Milling Company (NAMILCO) to enhance the company’s profitability in an environment of competition according to its Chief Executive Officer Bert Sukhai.

According to Sukhai the company had, over time, faced and overcome several challenges in its quest to improve its capacity to supply “a critical commodity” to the Guyanese market. Noting that those challenges included competition from both legal and illegal flour imports, Sukhai said that NAMILCO was not afraid of competition.

He said that the commencement of his own tenure as the company’s Chief Executive Officer in 1994 had coincided with a plan to significantly strengthen NAMILCO’s capacity to improve both its competitiveness and its efficiency. He said that those goals had revolved around the retooling of the company and that its investment in that exercise had paid “significant dividends.”

According to Sukhai the company had been failing to meet its maximum capacity of 3,000 bags of flour per day “because of the inefficiencies of what was then an old mill.” He said that the 1996 replacement of the old roller mills used for grinding wheat had been the catalyst for increasing the company’s production capacity to the current 4,200 bags per day.

According to Sukhai the company had undergone this significant retooling exercise in a manner that did not impact on its obligation to consumers since, while we were forced to close down for a period of about twelve days in order to complete that retooling exercise we still had sufficient supplies of flour to meet market demand, Sukhai said.

Established in 1969, NAMILCO is preparing for a commemorative period to mark the fortieth anniversary of what Sukhai said has been years of critical contribution to commercial life in Guyana. He said that NAMILCO had served as the vehicle for the processing of wheat into flour assigned to Guyana under the United States Govern-ment’s PL 480 Programme. “Our task at that time was to use the wheat to produce flour and to pay the government for that wheat at market prices. That is an achievement of which we are particularly proud given the fact that our operations were playing a role that was beneficial to the welfare of consumers during a difficult period,” Sukhai said.

Sukhai told Stabroek Business that while the arrangement with the Government of Guyana was conducted along commercial lines, NAMILCO was, at the same time, making “a further critical contribution” since, without the presence of the company the Government of Guyana would not have been able to use the PL 480 Programme. “At that time we were the only operation here with a capacity to produce flour and the alternative arrangement would have been for the government to access flour or other food items directly. The benefit of this arrangement is that we were providing employment for more than 100 Guyanese. “

And according to Sukhai NAMILCO had succeeded through its own competitiveness to overcome the challenge of illegally imported flour most of which was coming from Suriname and was not attracting duty. “We regard that as one of our more significant accomplishments as a company,” he said.