Weeks shy of the 13th anniversary of its commissioning Pomeroon Oil Mills, owned by businessman Alfro Alphonso is facing challenges, recovery from which will take some doing and is looking to diversify its product range.

The facility, commissioned in June 1999 by the late president Janet Jagan, had set its sights on securing and sustaining a lucrative regional market for coconut oil. However, it has been forced to temper its ambitions by force of circumstances which seem unlikely to change; at least in the immediate term.

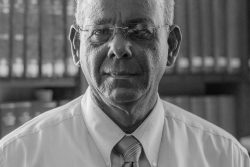

Operations Manager Ronald Abrams says the decline is due, primarily, to two factors. The first, he says, is the shortage of labour that has afflicted the entity resulting from what, for Essequibo’s business community has been the increasing migration of labour to the country’s more lucrative gold fields. Pomeroon Oil Mills is currently making do with a staff of 12; its operations require 40 workers.

The second and, arguably, bigger problem is the scarcity of raw material, coconuts; more specifically, copra, which is used in the production of coconut oil. Relying originally on supplies of coconuts and copra from the sprawling coconut grants of the Pomeroon area, the company now finds itself ‘shopping’ as far away as Wakenaam and Berbice. The shortage has arisen from a complex mix of shortage of labour to undertake the arduous task of producing copra from coconuts and the increased export price for the nuts. This has made it more profitable for farmers to target an obviously more lucrative, less labour intensive market and supplies to the mill have suffered.

Statistics provided by Abrams suggest that the shortfall of supplies to the mill has been staggering. Abrams says the facility has a capacity to absorb 600,000 pounds of copra per month, but it can still run a “comfortable” operation with supplies of between 400,000 and 500,000 pounds of the product. Over the past three years copra supplies to the mill has shrunk to around 170,000 pounds per month.

The company has sought to sustain current levels of supplies by relying on coconuts from its own 50-acre grant in the Pomeroon River, but the sheer scale of the decline has impacted on the profitability of the operations. Abrams explains that that having been forced to produce much of its own copra, the company must now find the labour to do so. More than that, transporting coconuts from as far as Berbice involves additional transportation costs and spoilage resulting from the sustained exposure of the coconuts to the sun. Abrams says that over the past three years production has dipped by at least 30 per cent.

Its ambition of continually increasing sales to the Caribbean seriously affected, Pomeroon Oil Mills’ regional sales are now restricted to two companies: Trinidad and Tobago-based Gopaul and Company and Lever Brothers of the Dominican Republic.

Equipped with a 15-tonne refinery, a copra-processing plant which can process all oil-bearing seeds cultivated in Guyana, a 700-metric tonne storage facility and a bottling plant, the company is determined to continue to supply its existing markets, though Abrams says the decline in operations has caused the management to look in the direction of diversification. Plans include additional coconut grant acquisitions and the production of canned coconut and coconut water.

Guyana produces relatively small quantities of coconut oil. The world’s leading producers include the Philippines, Indonesia, India, Vietnam and Mexico. Caricom is a net importer of oil for table consumption and industrial use and there is considerable potential for supplies of coconut oil to the region, USA, Canada and European Union markets, which are major destinations for coconut oil and coconut products.